hb-technik Ingredient Handling System

hb-technik Ingredient Handling System

Location:Australia

Description

This AS NEW hb-technik Ingredient Handling System is state of the art

See frequently asked Q&A below

Manufactured to handle among other products -

Bakery: batch size 200 to 300kg, 8 batches per hour, 2.4t materials per hour.

High tech, but easy to operate , that is ideally suited to solve your ingredient handling needs.

With superior accuracy that will assist you in producing a top quality product.

This system offered at a much reduced price of a system that would cost around New A$1,200,000.00

.

Contact us for more information and lets talk PRICE and what you're getting

call Alan on +61 417 615 573 or email him alant@assetinvest.com

Custom designed and computerised quality ingredient management system, bulk handling conveying and dosing. The automation of levels and line dimensions can be adapted to suit the characteristics of a Food or Beverage manufacturing business.

EQUIPMENT INCLUDES

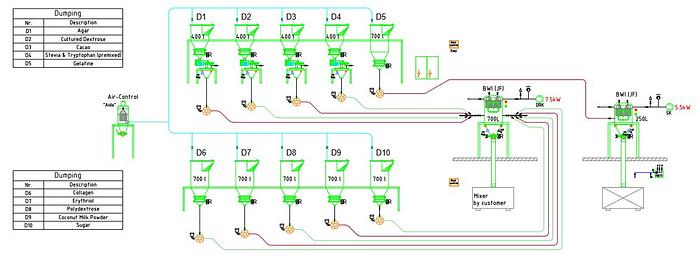

INGREDIENT HOPPERS AS BELOW

- 4 x 400 litre hoppers (dumping ingredient)

- 6 x 700 litre hoppers (dumping ingredient)

- 1 x 700 litre Weigh hopper

- 1 x 250 litre Weigh Hopper

- 1 X Vacuum Lifter for (ingredient bag hopper filling)

DUST ASPIRATION CONTROL

- Switchboard for electrical load control, will handle complex units with PLC control modules

SOME INTERESTING QUESTIONS AND ANSWERS BY SELLER

- If the system is capable to deliver ingredients to the two different weigh hoppers (700 litre and 250 litre) at the same time. Yes

- Could some of the ingredient hoppers that are currently connected to the 700-litre weigh hopper station be re-routed to the 250-litre weigh hopper. Yes

- If the current software can be used to link recipe systems to 2 x HB Technik static bench weighing system as illustrated below. Yes

- Do you have any information on cycle times/ speed of ingredient delivery to 700lt weighing hopper? Dependent on ingredients, historically Bakery, batch size 200 to 300kg, 8 batches per hour, 2.4t materials per hour.

- Ingredient range /+or- tolerance allowed when micro and bulk filling? Micro dosing (+ or – )15grams – Non micro hoppers (+ or – )100 to 200grams

- Confirm if the ingredients are all vacuumed to the weigh hoppers? or if some of them use the blower system? Both are vacuum/ two separate vacuum pumps. One is a 5.5kw pump just to transfer product from hopper D5 to the 250lt weighing hopper. This was a dedicated system to feed another production line. The second vacuum pump is the 7.5kw one which is used to transfer product from all the other hoppers to the 700lt weighing hopper. The two transfers can work independently and simultaneously.

THE MAIN BENEFITS OF USING HB-TECHNIK'S INGREDIENT HANDLING SYSTEMS INCLUDE:

- Precision and Consistency: The systems provide 100% accuracy in weighing, dispensing, and measuring ingredients, ensuring consistent product quality across batches12.

- Increased Efficiency and Productivity: Automation reduces reliance on manual operations, speeding up production processes and enabling higher output13.

- Cost Savings: By minimizing ingredient wastage and labor costs, the systems help reduce overall operational expenses. Bulk handling also eliminates the need for manual bag handling, further cutting costs15.

- Enhanced Safety and Ergonomics: Automated processes eliminate the need for physically demanding tasks, improving workplace safety and reducing the risk of injuries13.

- Customizability and Scalability: Systems are designed to meet specific client needs, with modular options available for both small-scale and large-scale operations. This flexibility allows businesses to expand their production capabilities over time14.

- Recipe Security and Control: The systems allow recipes to be stored securely by number rather than by name or ingredients, protecting intellectual property while maintaining ease of use1.

- Environmental Benefits: Bulk ingredient storage reduces packaging waste, contributing to a more sustainable operation1.

Call Alan Travell on +61 417 617 753 or email on alant@assetinvest.com for inspection or to discuss further

Specifications

| Manufacturer | HB-TECHNIK Bakery, batch size 200 to 300kg, 8 batches per hour, 2.4t materials per hour. |

| Model | INGREDIENT HANDLING SYSTEM - AS NEW - PRICE HIGHLY NEGOTIABLE - Located in QLD |

| Condition | Used |

| Stock Number | 24623 |