2011 KEY TECHNOLOGY ADR-5 AUTOMATIC REMOVAL SYSTEM

2011 KEY TECHNOLOGY ADR-5 AUTOMATIC REMOVAL SYSTEM

A$225,000 (AUD)

Location:Oceania

Description

The Key Technology ADR 5 automatic defect removal system inspects potato strips and automatically cuts out defects at production rates up to 16,200 lb./hr. It features high-resolution Vis/IR cameras, a belt conveyor, rotary cutter and high-speed vibratory conveyors to align, singulate, inspect and trim potato strips. New ADR 5 systems come with the CleanBelt clean-in-place system that combines passive and active cleaning to continuously remove starch from the ADR belt; it is offered as an in-field upgrade for installed ADR 5.

Information taken from www.key.net

The Key Technology ADR 5 automatic defect removal system is a cutting-edge solution designed to enhance the quality and yield of potato strips in food processing. It uses advanced technology to identify and remove defects, ensuring that only the best quality product moves forward in the production line.

Key Features:

- High-resolution Vis/IR cameras: These cameras provide detailed images of the potato strips, allowing for accurate identification of defects.

- Belt conveyor: This conveyor system transports the potato strips through the inspection and trimming process.

- Rotary cutter: This high-speed cutter precisely removes defects from the potato strips.

- High-speed vibratory conveyors: These conveyors align and singulate the potato strips for optimal inspection and trimming.

- CleanBelt clean-in-place system: This innovative system helps maintain hygiene by continuously removing starch from the ADR belt.

Benefits:

- Increased yield: By accurately removing defects, the ADR 5 system helps maximize the amount of usable product.

- Improved quality: Only the highest quality potato strips make it through the system, ensuring customer satisfaction.

- Enhanced efficiency: The automated process increases production speed and reduces labor costs.

- Reduced waste: By identifying and removing defects, the system minimizes waste and improves sustainability.

Overall, the Key Technology ADR 5 automatic defect removal system is a valuable investment for food processors looking to improve quality, increase yield, and enhance efficiency.

Please see VIDEO from KEY TECH - OEM on YouTube

The Key Technology Automatic Defect Removal (ADR®) systems process over 95 percent of the world's frozen potato strips. The ADR® combines high-resolution Vis/IR cameras, our patented belt conveyor, our patented rotary cutter, and our Iso-Flo® high-speed vibratory conveyors to align, singulate, scan, and trim potato strips with unparalleled speed and precision. This system eliminates manual trimming and inspection, and improves cutting accuracy and good-product recovery

The Key Technology Automatic Defect Removal (ADR®) systems process over 95 percent of the world's frozen potato strips. The ADR® combines high-resolution Vis/IR cameras, our patented belt conveyor, our patented rotary cutter, and our Iso-Flo® high-speed vibratory conveyors to align, singulate, scan, and trim potato strips with unparalleled speed and precision. This system eliminates manual trimming and inspection, and improves cutting accuracy and good-product recovery.

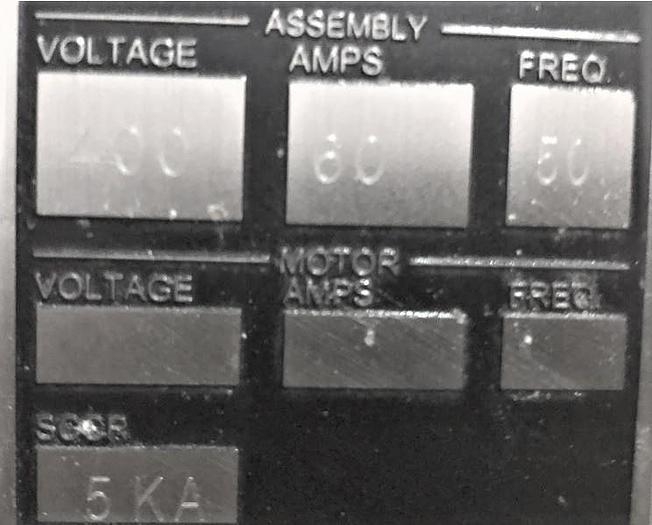

Specifications

| Manufacturer | KEY TECHNOLOGY |

| Model | ADR-5 AUTOMATIC REMOVAL SYSTEM |

| Year | 2011 |

| Condition | Used |

| Stock Number | 24624 |